WWTP design and construction

WE DEEPLY UNDERSTAND TREATMENT PROCESS AND ALWAYS TAKE LOCAL CONDITIONS INTO CONSIDERATION.

Conventional biological waste water treatment process was found and developed long time ago, it exists over 100 years and has been adopted from the nature. There are plenty of various process solutions offered on the market, providing efficient waste water treatment from organic and biogenic elements. Many such solutions are unified, standardized and successfully applied in different parts of the world.

At the same time we must pay attention to some specific local conditions in hot climate regions, for example, Arabian Peninsula Region. These specific conditions require correction and adaptation of process charts in order to guarantee high efficiency performance of treatment plants and reduction of

operation and maintenance cost. Among specific factors concerned we point out high temperature (up to 35°С ) of influent waste water and deficit of sweet water sources.

HIGH TEMPERATURE OF WASTE WATER

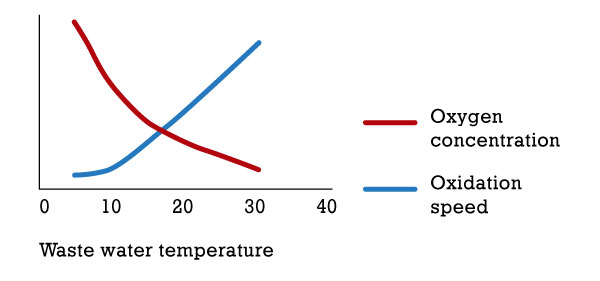

It is generally known that increase of waste water temperature results in:

- Increase of oxidation speed of impurities

- Decrease of dissolved Oxygen concentration

High oxidation speed

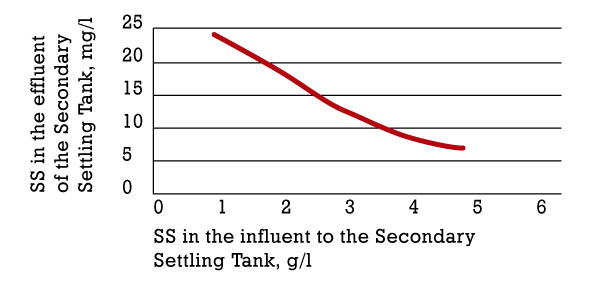

Higher waste water temperature makes sludge more active. Denitrification process is developing very intensively in Secondary Clarifiers, and as a result, suspended solids are carried away from the tank and treatment efficiency gets lower. In order to prevent from this negative process we need to reduce sedimentation time. Classic solution of this problem is separation of sludge mixture in Secondary Clarifiers with application of Lamella (Tubular Settlers). In the course of field tests we managed to find out the correlation between SS concentration in the effluent and sludge dose in Aeration Tank.

Specific feature of LBR process developed by ECOS is that increase of sludge concentration in Aeration Tank leads to increase of sedimentation efficiency. With sludge dose equal to 5 g/l concentration of SS carried away from Clarifiers is less, than 10 mg/l, even if waste water temperature is high (up to 35°C). Besides, when we manage to keep high sludge dose, we can reduce Aeration Tank volume, and, consequently, save capital cost.

Low concentration of dissolved Oxygen

When waste water temperature increases, upgrading of aeration system capacity is required. The existing method of estimation of Oxygen uptake to Aeration Tank must consider peak loads during 24 hours, consequently power consumption is going up.

LBR technology enables to reduce the impact of peak loads due to application of Balance and Denitrification Tank in the process chart. Balance Tank's function is to provide even concentration of impurities in influent waste water and even hydraulic load on downstream biological treatment facilities. LBR gives opportunity to reduce the rated power and electric power consumption even with high temperature of waste water.

DEFICIT OF SWEET WATER

Countries suffering from deficit of sweet water sources increase their demand to process solutions enabling re-use of treated waste water for agriculture or industrial purposes. Usually filters with granular filling are used for final treatment. ECOS has developed and successfully implemented its filters with ERSH® synthetic filling. It provides higher treatment efficiency (up to 70%) for SS comparing with conventional granular filling (up to 50%).

ERSH® filter systems provide SS concentration in treated effluent 5 mg or less. It has advantages, such as bigger dirt capacity (longer period of time between backwash operations compared with granular filters). ERSH® filling serves many years without replacement, it does not require big quantity of backwash water.